Description

Steps to fit your block with the patented McKissick Split-Nut ® Hook Retention System

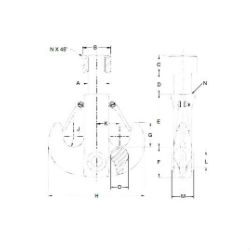

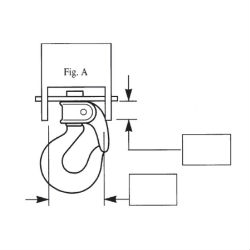

- Measure side plate to hook tip clearance and record in box “G” below. (The net length “H” dimension may be affected by holding the “G” dimension. If there is adequate clearance at tip of hook, the net length “H” dimension may be the dimension to specify).

- Remove hook and thrust bearing from existing crane block.

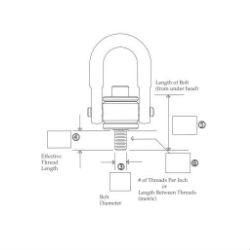

- Measure shank diameter and record in box “A” below.

- Measure nut thickness and record in box “B” below. The standard “B” dimension (shown above) is a minimum and will be utilized unless actual measured “B” dimension is required.

- Measure nut diameter and record in box “C” below. The standard “C” dimension (shown above) is a minimum and will be utilized.

- Measure thrust bearing thickness and record in box “E” below. If known, record thrust bearing manufacturer and stock number below.

- Measure trunnion thickness through the hook shank hole and record in box “F” within 1/32″.

- The required grip length “D” will be the addition of the “E” and “F” dimensions plus 0.06″ for running clearance.

- Determine the required hook size based on shank diameter and tonnage. Other shank /hook / tonnage combinations may be available. Your supplied information will be reviewed for the Split-Nut application.

- Complete the form and forward to your local Authorized Distributor for quotation.