Description

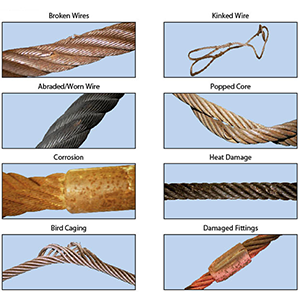

A wire broken under a tensile load that exceeds its strength by the “cup and cone” configuration at the fracture point (a). The necking down of the wire at this point shows that failure occurred while the wire retained its ductility. Shear-tensile fracture (b) occurs in wire subjected to a combination of transverse and axial loads. Fatigue breaks are usually characterized by squared-off ends perpendicular to the wire either straight across or Z-shaped (c & d).

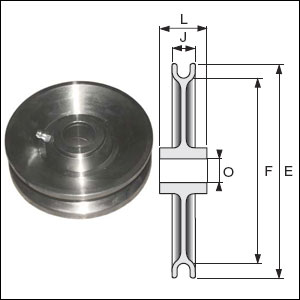

Specifications

Criteria for Replacement of Wire Ropes

When to Replace Wire Rope – Based on Number of Broken Wires

| ANSI*

Standard

|

Equipment |

Number Broken Wires

in Running Ropes

|

Number Broken Wires

in Standing Ropes

|

| In One

Rope Lay

|

In One

Strand

|

In One

Rope Lay

|

At End

Connection

|

| B30.2 |

Overhead & Gantry Cranes |

12 |

4 |

Not Specified |

Not Specified |

| B30.4 |

Portal, Tower & Pillar Cranes |

6 |

3 |

3 |

2 |

| B30.5 |

Crawler, Locomotive

& Truck Cranes |

6 |

3 |

3 |

2 |

| B30.6 |

Derricks |

6 |

3 |

3 |

2 |

| B30.7 |

Base Mounted Drum Hoists |

6 |

3 |

3 |

2 |

| B30.8 |

Flotaing Cranes & Derricks |

6 |

3 |

3 |

2 |

| B30.16 |

Overhead Hoists |

12 |

4 |

Not Specified |

Not Specified |

| A10.4 |

Personnel Hoists |

6** |

3 |

2** |

2 |

| A10.5 |

Material Hoists |

6** |

Not Specified |

Not Specified |

Not Specified |

* American National Standards Institute

** Also remove for 1 valley break.